Why Is Steel Manufacturing Essential for Modern Infrastructure?

The importance of steel manufacturing cannot be overstated in today's world. This industry serves as the backbone of modern infrastructure. According to the World Steel Association, global steel production reached over 1.9 billion metric tons in 2020, highlighting its vast scale. Steel is crucial for building roads, bridges, and buildings. These structures ensure connectivity and support economic growth.

In construction, steel's versatility shines. From skyscrapers to railways, it offers durability and strength. However, the industry faces challenges. The environmental impact of steel manufacturing raises concerns about sustainability. Reports indicate that steel production accounts for approximately 7-9% of global carbon dioxide emissions. This statistic urges the industry to innovate and adopt cleaner practices.

Despite these challenges, the demand for steel is projected to rise. A report from MarketWatch estimates a growth rate of 4.5% in the steel market by 2026. As cities grow and infrastructure ages, steel remains vital. Yet, the industry must balance growth with responsible practices. Steel manufacturing is key to our infrastructure, but it must evolve for a better future.

The Role of Steel in Building Sustainable Urban Infrastructure

Steel plays a crucial role in developing sustainable urban infrastructure. It is strong, durable, and versatile, which makes it ideal for many applications. According to data from the World Steel Association, steel is fully recyclable and can reduce energy consumption in buildings by up to 30%. This recycling aspect is vital for a greener future.

Urban development is growing rapidly. Steel contributes to constructing high-rise buildings, bridges, and transportation systems. In fact, approximately 85% of all constructed infrastructure around the globe utilizes steel. However, the manufacturing process can be energy-intensive and emit significant CO2. This contrasts with sustainability efforts.

**Tip:** Consider using recycled steel in your projects. It not only lowers emissions but also cuts costs. Balancing growth and sustainability is necessary. Communities need to reflect on steel production's environmental impact while promoting urban development. Implementing innovative technologies can help address these challenges. The future of urban infrastructure depends on responsible choices today.

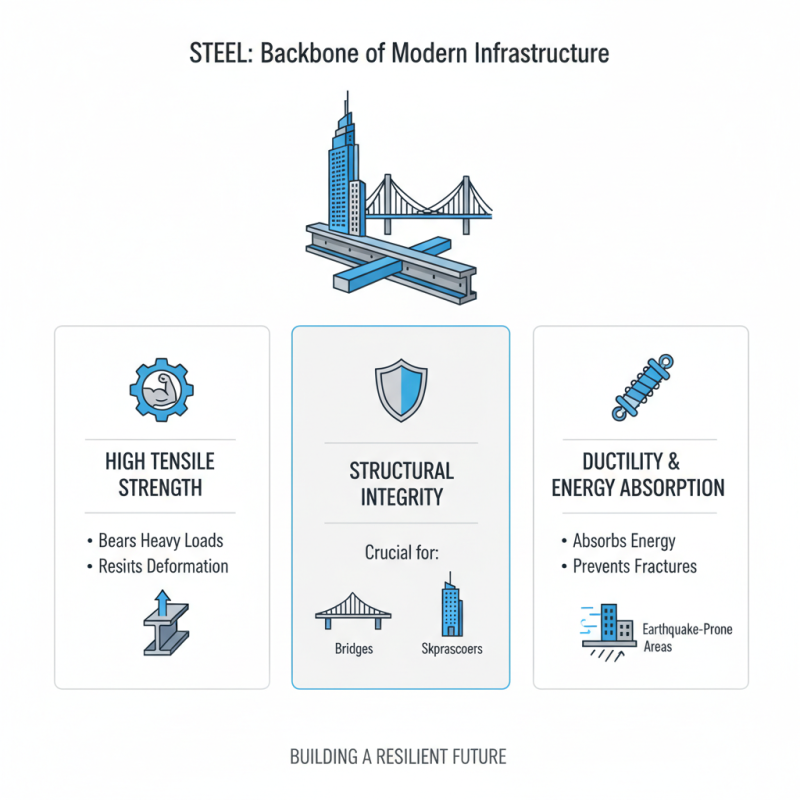

Key Steel Properties Contributing to Structural Integrity and Durability

Steel plays a crucial role in modern infrastructure. Its unique properties greatly contribute to structural integrity. High tensile strength allows steel to bear heavy loads without significant deformation. This makes it a popular choice for bridges and skyscrapers. Additionally, steel’s ductility enables it to absorb energy without breaking. This is particularly important in earthquake-prone areas.

Corrosion resistance is another key property of steel. Coated or treated steel elements can withstand harsh environmental conditions. However, not all steel is created equal, and some grades may not perform well in extreme scenarios. Regular maintenance is critical to ensure longevity. Engineers must constantly evaluate the structural health of steel components in buildings and other infrastructure.

Sustainability is also a growing concern. Steel production has environmental impacts that need addressing. The industry is working towards reducing carbon emissions. Innovations in recycling and alternative materials are promising. Balancing strength and sustainability is an ongoing challenge. Steel remains essential, but the industry must continually adapt.

Global Steel Production Trends and Their Impact on Infrastructure Development

Steel manufacturing is a cornerstone of modern infrastructure. Around the world, trends in steel production are vital to development. Countries are investing heavily in steel to support their growing urbanization. This move influences construction and energy sectors immensely.

The global steel output is fluctuating. Economic shifts can impact supply and demand drastically. When steel prices rise, it can delay projects. This can lead to increased costs and extended timelines. Infrastructure development suffers, and delays create bottlenecks.

Tip: Focus on sustainability in projects. Use recycled steel when possible. It can save resources and reduce costs.

Cities are often at the mercy of these trends. A sudden rise in steel demand can strain local supplies. Not every region has the resources to cope. This situation calls for strategic planning. Infrastructure must adapt to these changes.

Tip: Stay informed about market trends. This can help in effective project management. Anticipate potential shortages before they become a problem.

Economic Benefits of Steel Manufacturing in Construction Projects

Steel manufacturing plays a crucial role in the construction industry, providing essential materials for infrastructure development. Its impact on the economy is significant. Steel offers strength and durability, making it ideal for buildings, bridges, and highways. These structures can withstand environmental factors, ensuring longevity and safety.

The economic benefits of steel are evident in job creation and material efficiency. Steel production supports thousands of workers, from factories to construction sites. Each project stimulates local economies, leading to growth and investment. Steel is recyclable, reducing waste and lowering production costs. Projects often reuse steel, cutting down on expenses while saving resources.

Despite its advantages, the steel industry faces challenges. Environmental concerns regarding emissions need addressing. The shift to greener methods is slow, and this can hinder progress. Balancing affordable construction with sustainability is essential. Reflecting on these challenges can lead to innovative solutions, ensuring steel remains a cornerstone of modern infrastructure.

Why Is Steel Manufacturing Essential for Modern Infrastructure?

| Dimension | Details |

|---|---|

| Economic Contribution | Steel manufacturing accounts for approximately 2% of global GDP. |

| Employment | The steel industry provides jobs for over 4 million people worldwide. |

| Infrastructure Dependency | Steel is essential for the construction of buildings, bridges, and roads. |

| Sustainability | Innovations in steel manufacturing have reduced carbon emissions by up to 30% in recent years. |

| Recycling | Steel is one of the most recycled materials, with 85% of steel products coming from recycled material. |

| Versatility | Steel can be molded into a variety of shapes and sizes for diverse applications. |

Environmental Considerations in Steel Manufacturing and Infrastructure Design

Steel manufacturing plays a crucial role in modern infrastructure. However, the environmental impact of steel production demands careful consideration. The World Steel Association reported that steel production accounts for approximately 7% of global CO2 emissions. This statistic highlights the pressing need for sustainable practices.

To mitigate environmental effects, innovations in steel production are essential. Technologies like carbon capture and storage (CCS) show promise. These can potentially reduce emissions by up to 90%. Yet, adoption remains slow. Cost barriers and regulatory hurdles still pose challenges. Moreover, responsibility lies not only with manufacturers but also with infrastructure designers. They must prioritize sustainable materials.

Infrastructure projects often overlook their carbon footprint. While steel is a durable choice, its production leaves a significant mark. Alternatives like recycled steel or eco-friendly materials should be considered. A 2020 study revealed that using recycled steel could reduce energy consumption by 75%. Yet, this option is not always the default. Awareness and commitment are vital for change. The road to greener infrastructure requires collective effort and reflection.

Steel Manufacturing's Contribution to Modern Infrastructure

Related Posts

-

Top 10 Best CNC Engraving Techniques for Precision and Quality

-

Top 5 Benefits of Using a Metal Engraving Machine in Your Business?

-

How to Implement Manufacturing Automation Effectively?

-

How to Choose the Right CNC Machines for Your Business Needs?

-

Top 10 Automation Solutions Tips to Boost Your Business Efficiency

-

2026 How to Choose the Best Industrial Automation Solutions for Your Business?

Arsun Engineers is the well-known manufacturer, exporter, and supplier of highly operational machines.

Products

Automation

Get in Touch !

- 56/1 Vithalwadi GIDC, 364001 Bhavnagar, Gujarat, India

- +91 9426 816 961

- +91 7222 841 841

- sale@wallandmachinery.com