How to Leverage Manufacturing Technology for Competitive Advantage?

In today's competitive landscape, leveraging manufacturing technology is essential for businesses seeking to thrive. According to a McKinsey report, 70% of companies that embrace such technologies see significant productivity improvements. This indicates a clear link between technology adoption and success in manufacturing. Companies can optimize processes by integrating advanced technologies like automation and IoT.

However, the journey is not without challenges. Many organizations struggle with implementation. A Deloitte survey reveals that 33% of manufacturers find it difficult to adapt existing systems to new technologies. This leads to inefficiencies and potential setbacks. There's a pressing need for companies to reflect on their strategies and invest wisely.

Additionally, research from PwC shows that digital transformation can enhance supply chain visibility. But many companies remain hesitant due to perceived costs and complexity. The question remains: are they missing out on the competitive advantages that manufacturing technology offers? Embracing this shift may require a cultural change, but the potential benefits are undeniable.

Understanding the Role of Manufacturing Technology in Today’s Industry

In today’s fast-paced manufacturing landscape, technology plays a pivotal role. Advanced technologies such as automation, IoT, and AI have transformed how companies operate. A recent report by Deloitte indicates that manufacturers utilizing these technologies can boost productivity by up to 20%. This increase often stems from streamlined processes and enhanced decision-making capabilities.

However, the integration of manufacturing technology is not without challenges. Many firms struggle with the initial investment and skill gaps among their workforce. According to a McKinsey study, 87% of executives acknowledge that their organizations lack the necessary skills for digital transformation. As manufacturers attempt to adapt, they must also reflect on their approach and ensure ongoing training and support for employees.

Additionally, while technology offers significant advantages, companies must also be cautious. A heavy reliance on automated systems can lead to vulnerabilities. Cybersecurity threats are rising as more devices connect to the internet. A 2023 Cybersecurity report highlights that 60% of manufacturing firms experienced a cyber incident in the past year. Balancing innovation with security remains a crucial consideration as companies navigate the evolving industrial landscape.

Identifying Key Manufacturing Technologies for Competitive Advantage

Manufacturing technology plays a crucial role in gaining a competitive edge. Companies can enhance efficiency, reduce costs, and improve product quality. Key technologies include automation, AI, and IoT. Each of these can transform operations, but implementation comes with challenges.

Automating processes can streamline production, but it may require significant upfront investment. Workers need training to adapt. The Internet of Things (IoT) enables real-time data collection. This can enhance productivity. However, integrating these systems can be complex. Companies must prioritize security to protect sensitive data.

Tips to consider: Invest in employee training to embrace new technologies. Collaborate with tech partners for smoother transitions. Evaluate technologies regularly to ensure they align with business goals. In the race for innovation, reflecting on setbacks is crucial. Companies must learn from mistakes to refine their strategies.

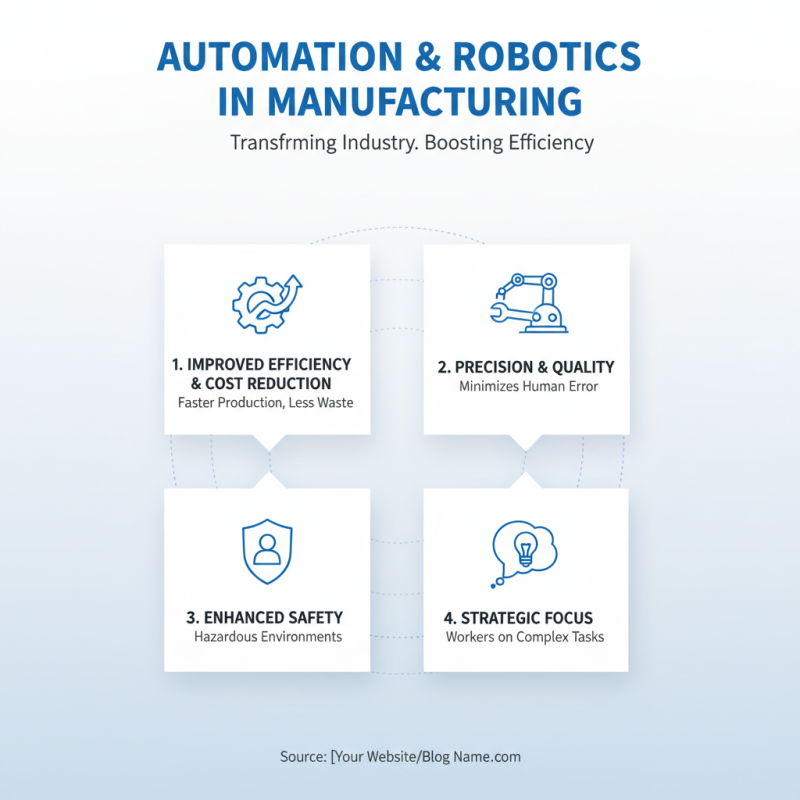

Evaluating the Benefits of Automation and Robotics in Manufacturing

Automation and robotics in manufacturing are transforming the industry. Companies are adopting these technologies to improve efficiency and reduce costs. Automated processes can perform repetitive tasks with precision, minimizing human error. Robots can operate in environments that may be hazardous for employees. This adds a layer of safety and allows workers to focus on more strategic activities.

However, embracing automation isn't without challenges. Initial investments can be substantial. Smaller manufacturers may struggle to adopt these technologies. Additionally, there's a need for skilled workers to manage and maintain automated systems. The shift can ignite fear within the workforce about job security. Organizations must be ready to address these concerns and invest in training programs.

The benefits of automation are visible, yet they require careful evaluation. Companies must analyze production goals and workforce dynamics. Automation is not a one-size-fits-all solution; it must align with specific needs. Finding the balance between technology and human input is crucial. Ultimately, the focus should be on enhancing productivity while fostering a motivated workforce.

Implementing Data Analytics and IoT for Enhanced Production Efficiency

Manufacturing technology is evolving rapidly. Implementing data analytics and IoT can significantly enhance production efficiency. Many factories now rely on real-time data. Sensors monitor machinery conditions, checking for issues before they escalate. This foresight reduces downtime and boosts output. Yet, the journey is not without challenges.

Data can sometimes overwhelm decision-makers. Too much information can lead to analysis paralysis. Companies must learn to filter what matters. Choosing the right metrics is crucial. Prioritizing actionable insights over raw data ensures teams stay focused. Integrating IoT devices can also present hurdles. Compatibility issues may arise, necessitating additional investments or system upgrades.

Despite these difficulties, the rewards are substantial. Improved efficiency can lead to cost savings. Real-time monitoring allows for quicker adaptations to production changes. Companies that navigate these challenges can gain a competitive edge. They become more agile and responsive to market demands. Embracing technology is essential, but it requires thoughtful implementation.

Leveraging Manufacturing Technology for Competitive Advantage

This chart illustrates the improvement in production efficiency over the years, demonstrating how the implementation of manufacturing technology, including data analytics and IoT, can lead to competitive advantage.

Developing a Strategic Plan for Technology Adoption in Manufacturing

In today's fast-paced manufacturing environment, adopting technology effectively can be a game-changer. A strategic plan should start with a thorough assessment of current processes. Understand where delays and inefficiencies occur. Look for technologies that can simplify tasks or enhance production speed. Regularly review performance metrics to identify critical areas for improvement.

Next, involve your team in the technology adoption process. Employees often have insights that can shape your strategy. Host workshops or brainstorming sessions. Gather feedback on potential technological solutions. This dialogue can surface concerns or suggestions that leaders may overlook. Emphasizing collaboration fosters a culture open to change.

It's important to recognize potential pitfalls. Some may resist new methods out of fear. Training is essential but can be time-consuming and costly. Be prepared for setbacks during implementation. Not every technology will yield immediate results. Monitoring progress and adapting your approach is key. Embrace the need to revise plans as you learn from the experience. This flexibility ensures that your strategy remains relevant and effective.

Related Posts

-

Why Is Steel Manufacturing Essential for Modern Infrastructure?

-

Why You Should Consider a Wood Engraving Machine for Your Projects?

-

Top 5 Benefits of Using a Metal Engraving Machine in Your Business?

-

2026 How to Choose the Best Industrial Automation Solutions for Your Business?

-

How to Choose the Right CNC Machines for Your Business Needs?

-

Top 10 Best CNC Engraving Techniques for Precision and Quality

Arsun Engineers is the well-known manufacturer, exporter, and supplier of highly operational machines.

Products

Automation

Get in Touch !

- 56/1 Vithalwadi GIDC, 364001 Bhavnagar, Gujarat, India

- +91 9426 816 961

- +91 7222 841 841

- sale@wallandmachinery.com